1. Laboratory-grown diamonds have essentially the same physical and chemical characteristics as natural diamonds, but they are not identical, and they are easily detected.

Laboratory-grown diamonds are produced in two to three weeks using two different methods: high pressure high temperature (HPHT) and chemical vapor deposition (CVD). Each method leaves growth marks and telltale signs that are distinctive of an artificially produced diamond, this is how they can be identified using professional instruments. Moreover, most synthetic diamonds need to be color treated to correct distortions created during the industrial production process.

2. Laboratory-grown diamonds are produced in a matter of weeks, primarily in factories situated outside of the United States, mostly in Asia.

Most laboratory-grown diamonds are not produced in the United States but in China, India, and Singapore. There is a lot of investment in new production capacity in Asia today, and the share of Asian producers is likely to increase further. Laboratory-grown diamond producers often make claims about their product being “eco-friendly,” “transparent,” and “sourced with integrity.” However, these claims are usually vague and unsubstantiated and the origin of the product is almost never disclosed.

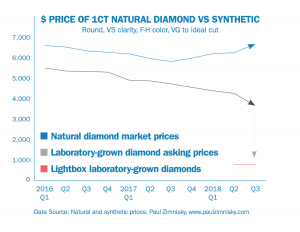

3. Retail price continues to erode as the costs of production decline.

Production costs of laboratory-grown diamonds are driven almost entirely by electricity usage, which is why some producers move to regions where electricity costs are low. This explains why, over time, as technology improves, production costs will continue to decline. In the case of colored gemstones such as rubies, sapphires, or emeralds, the price of synthetic stones is about 10 percent of that of the natural stone.

Also important to know: Due to economies of scale, the larger the synthetic diamond produced, the lower the cost per carat—a stark contrast to natural gemstones.

As an industrial product, a laboratory-grown diamond has no resale value, and its price is falling rapidly.

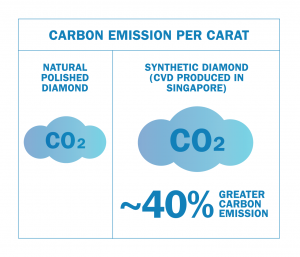

4. The carbon emissions for a 1 ct. synthetic diamond are similar to, and sometimes greater than, those for an equivalent natural diamond.

When making comparisons with natural diamonds, synthetic diamond manufacturers often quote theoretical carbon emissions for synthetic diamonds that assume that they use 100 percent renewable energy. In reality, synthetic diamond production today primarily uses electricity generated by fossil fuels, mostly in China, India, and Singapore. Rigorous comparisons require case-by-case analysis, depending on producer and country grid emission factors. Taking the example of a 1 ct. synthetic diamond produced in Singapore using the CVD method, where a significant volume of the CVD synthetic diamonds are produced, the carbon emission per polished carat is approximately 40 percent higher than for natural polished diamonds.

Source: DPA Analysis

5. A large majority of consumers do not consider laboratory-grown diamonds produced in a factory to be real diamonds because they are not formed naturally in the Earth.

A Harris poll from May 2018 shows that 68 percent of U.S. consumers believe that a laboratory-grown diamond produced in a factory is not a “real diamond.” Just 16 percent of respondents believe they are. Other surveys show that as consumers learn about the lack of inherent value of synthetic diamonds, fewer consumers consider them to celebrate important moments in their lives, even if a growing proportion consider them for fast-fashion jewelry.

68 percent of U.S. consumers believe that a laboratory-grown diamond produced in a factory is not a “real diamond.”

Source: Harris Poll, 360 Study, for DPA