Ankit Shah empties two parcels of natural rough diamonds onto a desk as breezily if he were divvying up a bag of candies. At first glance, each pile of transparent pebbles, rounded like river stones, looks identical. But the parcel on the right, Shah says, is slightly more valuable: $1.4 million, compared with $1.3 million for the one on the left.

It’s mid-May, and we are at Ankit Gems’ factory in Surat, the city in India’s Gujarat state where more than 90% of the world’s rough diamonds are cut and polished.

Shah, the company’s director, points to the pricier goods: “When these are cut and polished, they will be between 2½ to 4 carats on average.”

To American jewelers accustomed to thinking of India as a hub for the world’s smallest and least expensive diamonds, the fact that Ankit specializes in larger, finer goods—especially fancy shapes and, lately, fancy yellows—may come as something of a surprise. But for Shah, the story of how a center once known for manufacturing cheap, brown smalls has transformed into a steady source of finely polished multimillion-dollar stones is synonymous with his family’s history.

“The diamond industry has been in Surat for almost 70 years,” he says. “But in the last 20 years, we’ve focused on larger diamonds, from 50 points up. Ankit was established in 1985 by my father and two uncles—they had a vision for venturing into larger goods.”

That vision, which the Shahs helped solidify in 2016 when they began operating from their new 150,000-square-foot factory in Surat, has proved attractive to influential American retailers, such as my host in India, Seattle-based Ben Bridge Jeweler, a client of Ankit’s since 2018.

Last year, the retailer brought me to Botswana to learn more about its diamond sourcing program. This year, I’ve joined a group of six editors—as well as a trio of Ben Bridge executives, including CEO Lisa Bridge (whose husband, Gilad Berenstein, has come along for the ride), vice president of marketing Stacy Speicher, and vice president of merchandise Angela Hope—on an epic jewelry journey across India to bear witness to what happens when the rough mined by De Beers in Africa and Canada, and sorted in Botswana, makes its way to the next stage of Ben Bridge’s global supply chain, and, eventually, into the company’s high-end, customizable diamond jewelry collection, Bella Ponte.

The tour of Ankit’s state-of-the-art facility is a lesson in micromanagement: essentially, how not to lose sight of all those tiny yet extremely precious things despite the fact that they are being physically transformed under your watch.

“When the rough comes in, every stone gets its own parcel,” Shah explains, as he shows us the folded paper, or brivka, used to hold each diamond. “They put the stone inside. They put the weight of the individual stone [on the paper]. They put what color the machine thinks it is, what the fluorescence inside is, and what type of rough it is—makeable, sawable, cleavage, or something like that.

“Then you use the weighing scale to measure the stone, the color machine to see the color, and it is all assigned an RFID number,” he adds. “But as you follow the stones through the factory, you’re going to see a whole story develop here. It’s fascinating the way that they keep track and the notes and the checks that happen along the way.”

Fascinating—and intricate. To help us understand the process on a more granular level, Shah hands out flow charts detailing what happens to each stone, from the moment it arrives and is placed in a single parcel to the point when it is ready for sale, having been scanned, planned, sawed, blocked, polished, and imaged.

Each step is designed so that Ankit can optimize the value of its stones—the name of the game when it comes to natural diamonds. That means taking into account a host of factors, chiefly carat weight, shape, and clarity.

To ensure the cutters are able to maximize clarity, Ankit employs Sarine’s Galaxy technology to map out the inclusions in each stone. Optimizing a diamond’s shape, however, depends on where it will be sold, given that each market has distinct preferences.

“America is predominantly, of course, a market for rounds, but it’s still also a big fancy-shaped market,” Shah says. “But America is not sticking to one fancy shape. Ten years ago princess was the shape, and now nobody wants princess. Everybody wants longer shapes, like a long cushion, long radiant, or long oval. So in America the taste keeps changing.”

As he speaks, I think (not for the first time) about the codependence of our two markets: America, with its seemingly insatiable demand for diamond jewelry, and India, with its seemingly limitless pool of labor. (Incidentally, Ankit Gems employs 1,500 people at its Surat facility alone, including about 350 polishers—our group was extremely impressed to learn that every day, every single employee gets a free lunch.) That dynamic—of desire on one end of the supply chain, and fulfillment on the other—made an impression on me 20 years ago, on my first visit to this enchanting country, and it continues to make an impression on me today.

The elephant in the room is, of course, the lab-grown trade, much of it fueled by CVD goods made in Surat (but not by Ankit, which works only with natural diamonds). Over the past two years, thousands of local diamond factory workers who once specialized in cutting and polishing natural diamonds have turned their attention to created gems, in part so factory owners can keep their employees busy during an uncertain time for the natural diamond business.

Shah likens the phenomenon to a gold rush: “Let’s say 60%, 70% of the factories are now doing lab-grown.”

When I ask him about the competition that’s generated, he acknowledges that in the smaller goods—say, 70 points to 1 carat—the market has slowed “because those customers have moved to lab-grown.” But, he says, “1.5 to 5 carats are doing very well. Anyone spending $15,000 to $20,000 is still buying natural.”

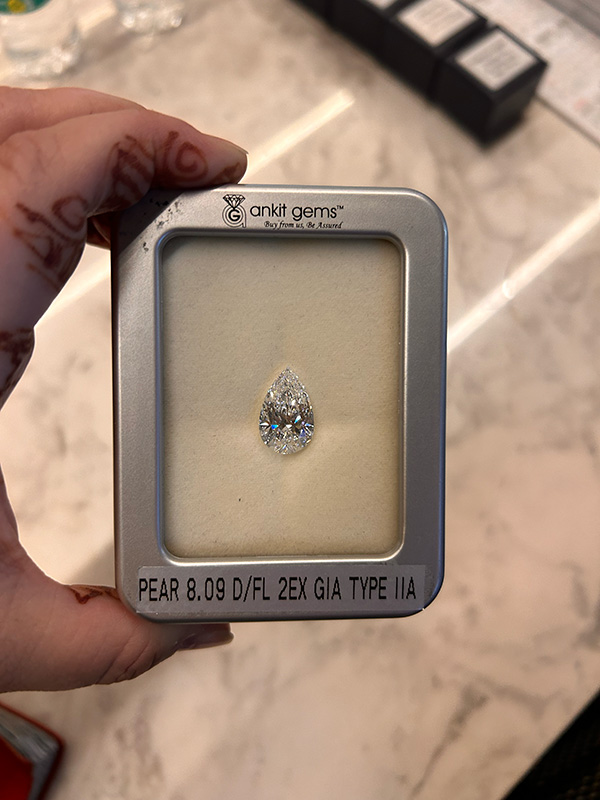

We finish the tour with a closing presentation in the conference room that handily drives that point home. The bowls of mangoes and dishes of cashews on the conference table are a thoughtful touch, but it’s the diamonds we’re after—specifically, the 20 or so impressively large stones contained in little cassette cases displayed at the head of the table.

“This is a very rare pear-shape, an 8-carat, D flawless,” Shah says, as he picks up the nearest case. “It’s about $800,000.”

Nearby, an array of yellows, from light to vivid, beckon us with their buttery hues. The collection, which contains a 12.5 ct. vivid yellow, totals about $3.5 million, Shah says.

I place the 12.5-carater between my fingers and angle it in the daylight flooding in through the windows just as Lisa Bridge happens by. “My God, that’s worthy of admiration,” she says.

She’s talking about the stone, but she may as well be talking about Ankit’s factory, and, for that matter, Surat itself. In less than two decades, the city, once a bleak industrial backwater, has become one of India’s 10 richest.

What do the next 20 years hold for the trade that’s helped build much of that wealth? If Ankit’s operation is any indication, India’s diamantaires are just getting started.

Top: The view from Ankit Gems’ 150,000-square-foot diamond-cutting factory in Surat, India (photo courtesy of Ankit Gems)

- Subscribe to the JCK News Daily

- Subscribe to the JCK Special Report

- Follow JCK on Instagram: @jckmagazine

- Follow JCK on X: @jckmagazine

- Follow JCK on Facebook: @jckmagazine